Cable Fire Protection

Meeting industry standards

What is FS Cable Fire Protection?

What is FS Cable Fire Protection?

FS specializes in Class Approved passive fire protection of electrical cables by way of cable coating. Our applications can be completed on live cables with no disruption to your operations.

FS manufactures an intumescent coating system designed for internal or partially sheltered applications and an ablative coating system for internal and external applications.

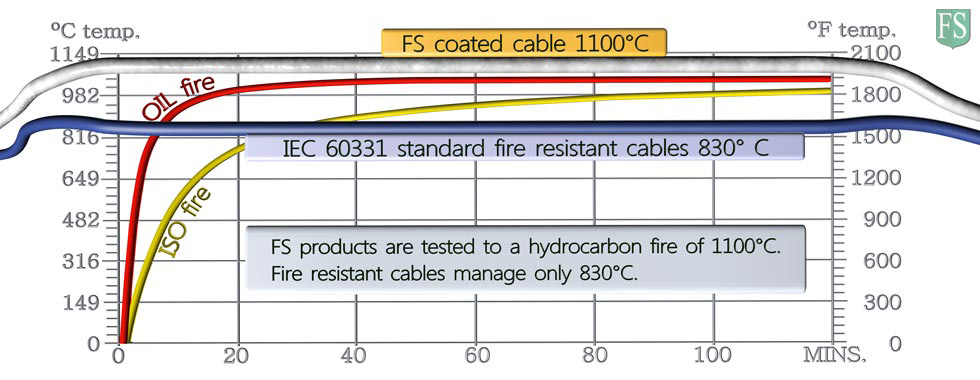

Both coating systems are tested to meet the IEC Publication 60331 and 60332 requirements and are additionally tested to Hydrocarbon Fire Curve of 1100° Celsius for a minimum of 60 minutes. Our intumescent coating system is also tested fire resistant for up to 3 hours at 830° Celsius.

Survive exteme temperature over time

Survive extreme temperature over time

The IEC 60331 standard fire-resistant cable can withstand only 830° C (1526° F) in a fire situation, while FS coated cables can survive a hydrocarbon fire of 1100° C (2012° F) for up to 60 minutes – without any problem to the insulation or the electrical properties of the cable.

Why FS Cable Fire Protection?

Why FS Cable Fire Protection?

FS cable coating systems protect against loss of life and loss of production. Our coatings prevent flame propagation and prevent escalation from a small fire to a major incident. FS cable fire protection minimizes impact from short circuits, removes cables as a source of combustion and prevents the release of toxic & poisonous gasses.

Even the smallest of fires from a short circuit or external source can easily cause an enormous loss of production. Industry standards dictate that a damaged cable that takes more than 6 hours to replace is classified as critical and should be fire technically upgraded.

Electrical cables are a natural pathway for a fire to spread rapidly. With FS cable coatings applied the possibility of a fire spreading through the cable routing is eliminated.

Extend the lifespan of your cables

Global insurance companies recognize FS Class and Type Approved cable coatings and even recommend the use of them to protect critical cable routings. This often results in a significant lowering in annual premiums.

Compared to costly installation and expensive maintenance programs of Active Fire Protection Systems, cable coating is a better and more cost-efficient alternative.

Active systems are not all designed to extinguish a fire but merely contain it at its early stage. Active systems are reliant on the correct mechanical configuration or manual triggering.

FS fire protected cables always work to ensure that cables remain in service during the first critical stage of a fire incident. This ensures circuit integrity continuity of emergency services and operational electrical components. Most importantly the cables do not need to be replaced after a fire incident.

Compared to both flame-retardant and fire-resistant cables, FS cable coating is a safer and more cost-efficient alternative. Typically, these cables are tested to 830° C for limited periods which in a normal fire scenario is insufficient and certainly so in a Hydrocarbon fire scenario. These cables will need to be replaced or at least repaired after a fire resulting in costly downtime and loss of production. FS coated cables have superior properties and will not need to be replaced if the fire is extinguished within a reasonable time.

Toxicity from burning flame-retardant and fire-resistant cables outer sheaths can mix with humidity in the air or water from active systems and create Hydrochloric Acid which can severely damage sensitive electrical components and systems as well as weakening steel and degrading the concrete. All resulting in loss of life and dramatic damages to critical components.

FS coated cables have excellent Mechanical Resistance and are strong enough to sustain physical abuse such as impact from falling objects and will remain effective protection for many years. Some of FS’s oldest clients have cables that are still in service twenty-five years after our initial application.

Read More

Cable repair and fire protection at Pulp and Paper Mill

Passive fire protection vs active systems

How FS Cable Fire Protection Work

How FS Cable Fire Protection Work

FS Intumescent coating expands up to 100 times its thickness. To understand and identify your concerns regarding the safety of your cables, we normally conduct an on-site survey followed by a detailed survey report with suggested solutions. This service is offered with no commitment from the client. Contact us today for a free online consultation.

FS’s experienced surveyors will work with you to understand your concerns and identify the opportunities to lower the risks and increase the resilience of your cables.

In the survey report, we document the current and likely future conditions of your cables. Our recommendations along with budgetary indications are then presented to you confidentially.

Turnkey applications are delivered by our own highly skilled technicians using only FS Class Approved products, and the work process concludes with a full documentation package including Completion Report and Warranty Certificate, supported with relevant Class Approvals and Testing reports.

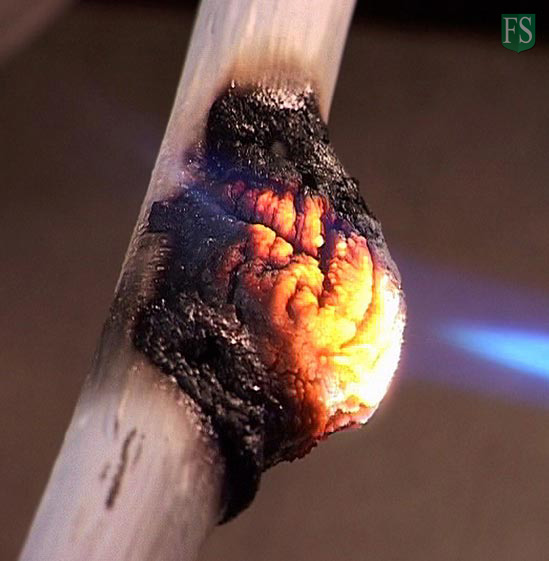

FS has two coating systems for Fire Protection. The first is an intumescent cable coating that expands up to 100 times during a fire, creating a thick char foam that shields the cables from fire damage. The second one is an ablative coating that protects the cable by the physical reaction which converts large amounts of energy and water vapor that shields the cables in a fire situation.

The coating application is usually performed with a heavy-duty airless sprayer and it will cover all cables from end to end within the designated area of concern.

Cable Fire Protection and the Environment

Cable Fire Protection and the Environment

Active versus Passive Fire Protection. FS systems

reduce or eliminate the need for active fire suppression

systems, which use millions of gallons of chemically treated

water annually. During fires, this water is polluted further by fire by-products before it seeps into local watersheds. Protecting electrical cables with passive FS systems shields ecosystems from unnecessary damage. At FS, we are committed to continuing our efforts towards sustainability and reducing our own and our end-users’ impact on the environment.

Videos

Videos

Videos & Brochures

Fire protection for industrial plants

Fire protection for cruise ships

Fire Protection, Cable Repair, and Lifetime Extension for offshore installations

Fire Protection of Electrical Cables. Intumescent and ablative firestop cable coating

You might also be interested in

You might also like

Cable Life Extension

A cost-effective solution to prevent premature or unnecessary cable replacements.

Non-disruptive Cable Repair

Repair and coating system for damaged or brittle LV to HV cables, with a minimal need for shutdown and loss of production.